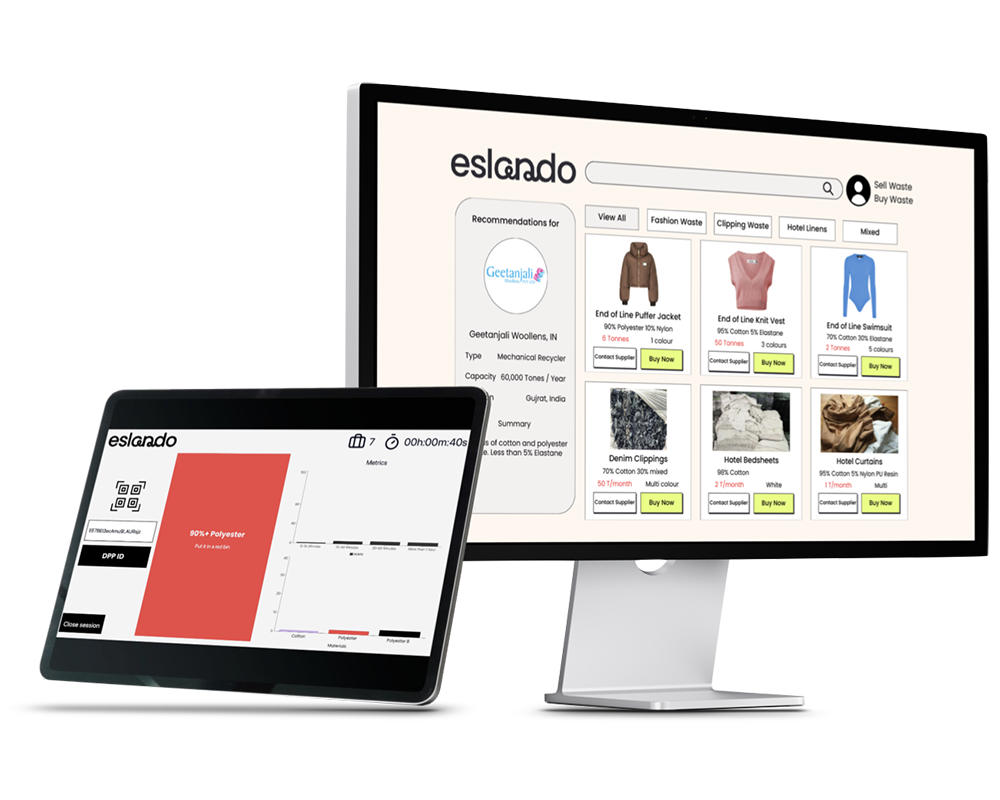

Partnering with Eslando

Eslando connects sorted textile waste to specialist fibre-to-fibre recyclers across the world.

Through this partnership, our collected textiles can be matched to the right recycling technology based on fibre type and quality, increasing the share that goes back into new fibres.

Fibre-to-Fibre Exploration

We are actively testing advanced fibre-to-fibre recycling methods. Recently, we shipped a bale of end-of-life clothing to India for trial processing, helping us evaluate how worn textiles can be broken down and spun into new materials at scale.

With less than 1% of textiles currently recycled back into new fibres, these pilots are an important step forward.

Building for the Future

In 2024, Roberts invested £5 million into our Cheshire headquarters, creating one of the UK’s largest dedicated textile recycling facilities.

The 80,000-square-foot site has doubled our processing capacity and is equipped with advanced sorting lines to prepare millions of garments every month for reuse or recycling.

Not all textiles are suitable for reuse. To prevent these materials from becoming waste, we’ve developed Purpose Driven Products – an initiative to create practical, useful items from non-reusable textiles.

- Industrial rags for local industries

- Insulation materials for wall cavities and carpet underlay, including our own reception area.

- Punchbags filled with textile strips, donated to a local boxing gym.

- Moulds and bio-resin products, such as on-site cup coasters made from textile fluff

- Prototypes for gym flooring, including our on-site gym fitted with flooring made from recycled footwear that had failed QC

Truly, products that serve a purpose.